Nanotechnology to alter animal health, food systems

by Robin Booker (Article in The Western Producer Magazine) - Link

Biological sensors based on nanotechnology are being developed by Canadian researchers and may soon be commonplace on Canadian farms.

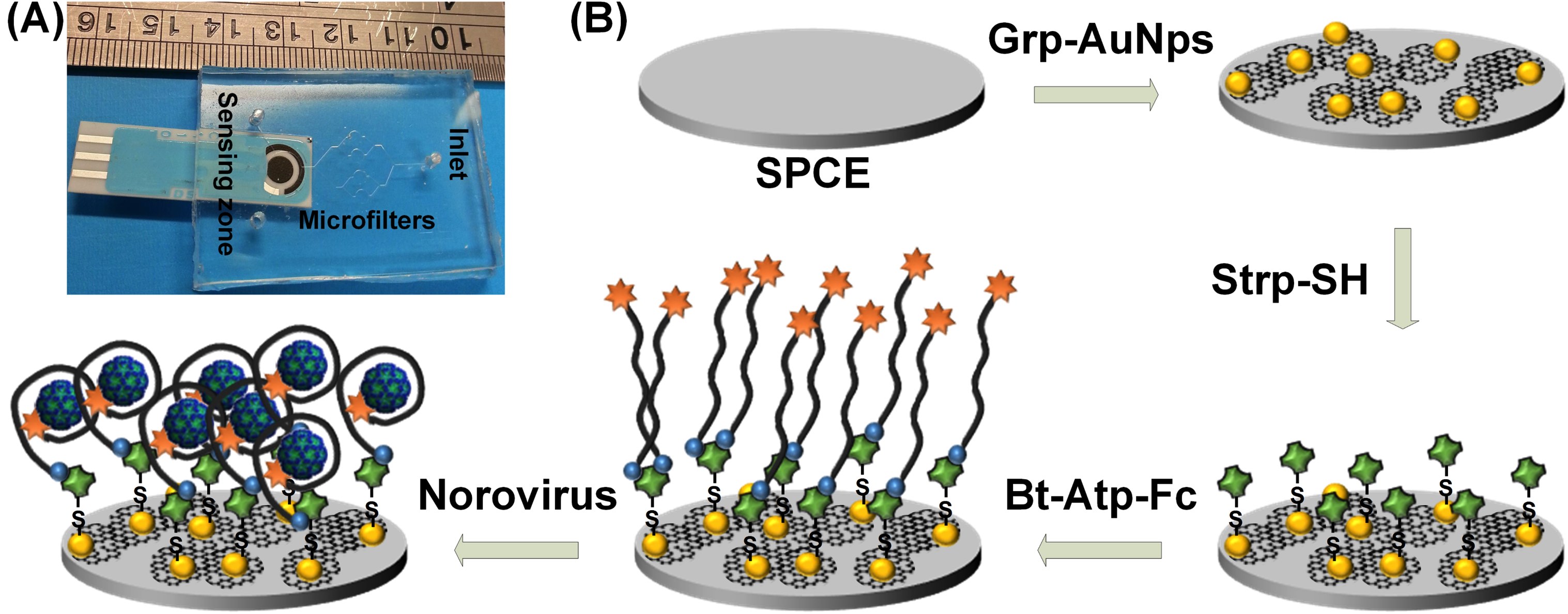

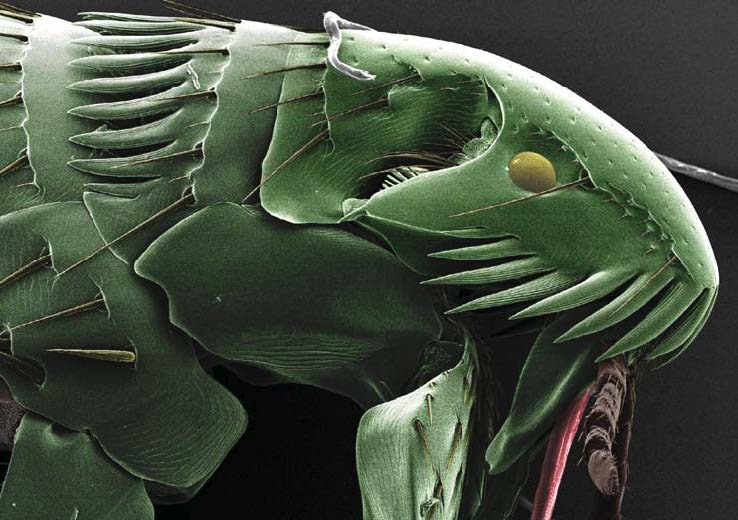

A biosensor device relies on a biological element such as an enzyme or bacterium to react with a target substance such as a spore or virus. This reaction is monitored by a transducer that converts the biological response into an electrical signal.

For instance, research scientist Susie Li is developing a biosensor that can differentiate sclerotinia spores from other spores in the air.

Li, who works at Alberta Innovates Technology Futures, developed the biosensor’s chip with gold nanoparticles bonded to it. These nanoparticles are also attached to antibodies that only attach to sclerotinia spores. When the antibodies attach to a sclerotinia spore, the gold nanoparticle sends a signal to a transducer connected to wireless technology. “You transmit that signal to a little box, like Bluetooth technology, and then that can transfer to an electronic device like a cellphone. You just need to download an app and then you can use it,” Li said.

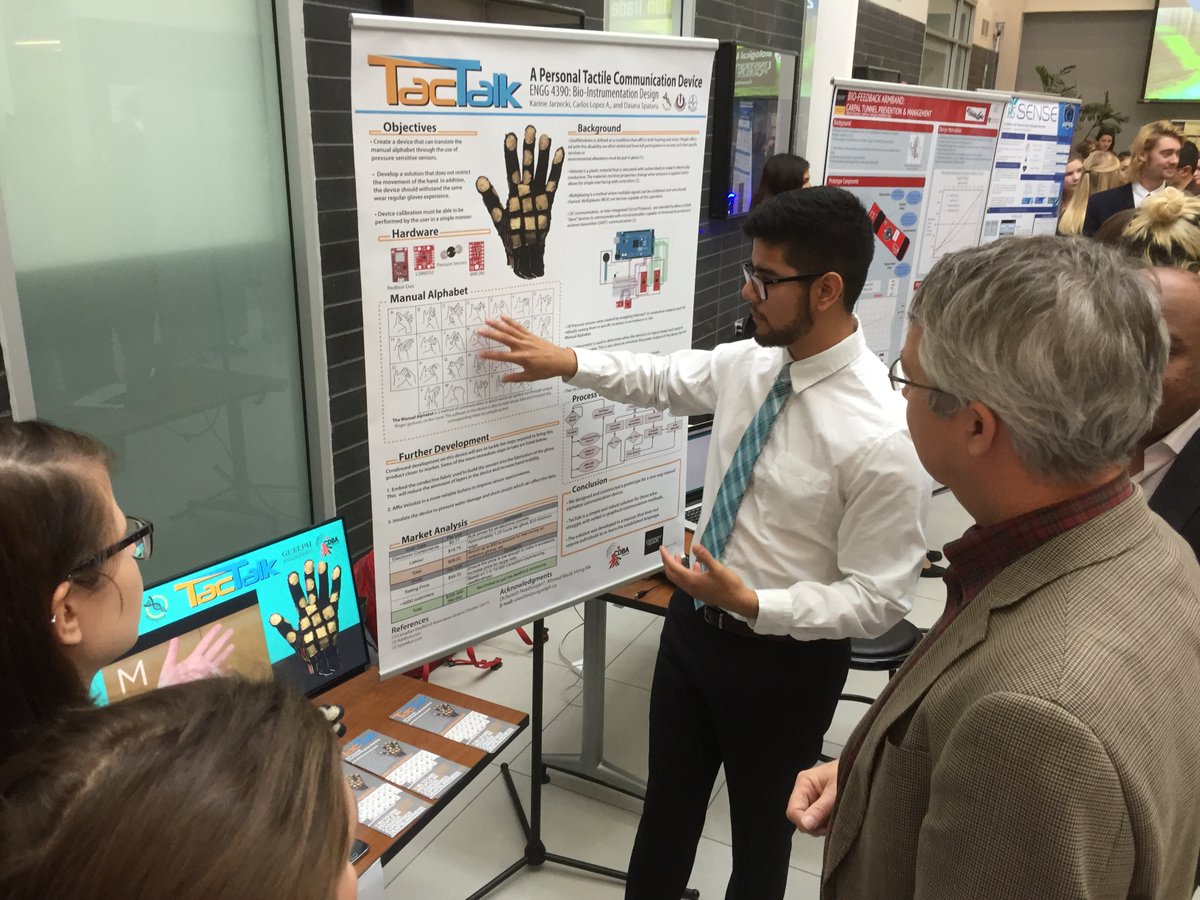

Suresh Neethirajan, director of the Bio Nano Laboratory at the University of Guelph, holds a device he helped develop that uses nanobiosensors on paper test strips to detect multiple kinds of virus, bacteria and food allergens.

This sensor can send farmers text messages when a specific threshold of sclerotinia spores has been reached in their fields.

“I hope it could be a revolution because right now, you have to go to the field to find out and it’s time consuming. It’s also because you have to pick up a diseased leaf or petals and then you send that back to a lab,” Li said.

It currently takes days to get results back from a laboratory when testing for sclerotinia, and the spraying window for the disease is very short in canola.

The sclerotinia detector Li built can detect as few as five sclerotinia spores.

She is currently miniaturizing the detector and expects a field-ready model to be on the market within five years.

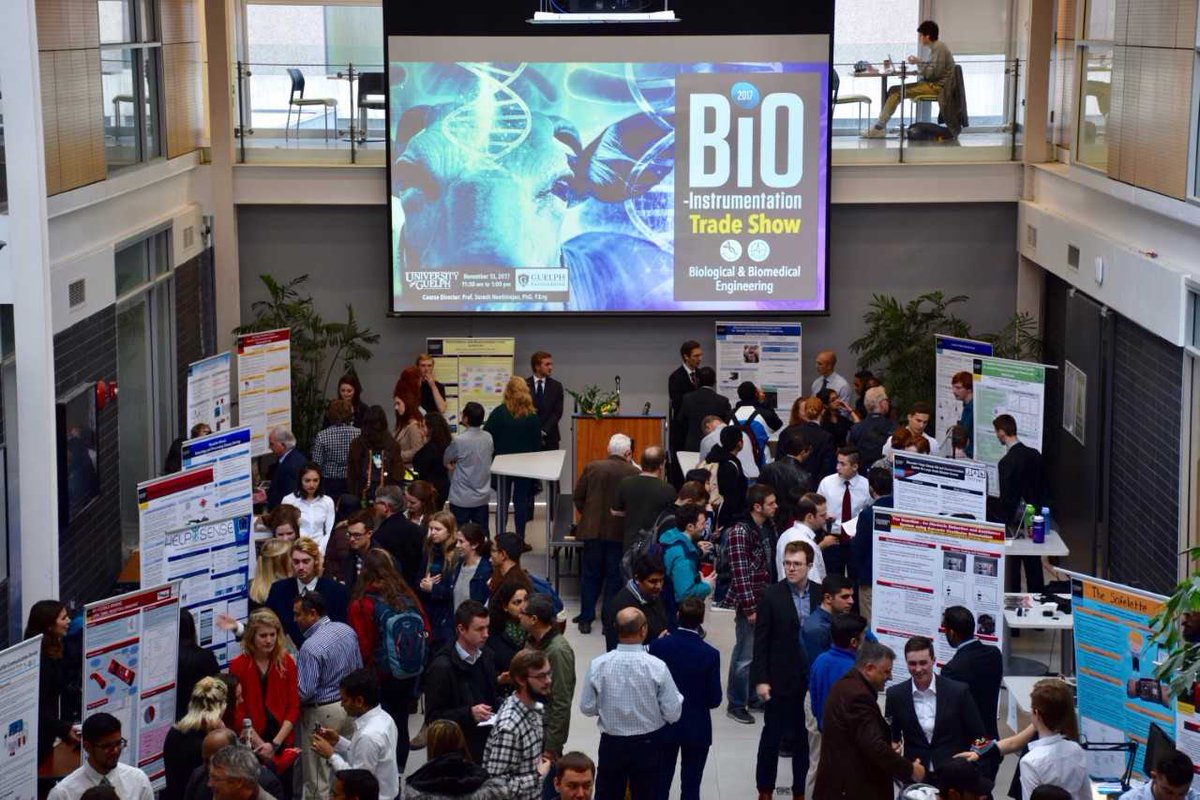

Nanotechnology-based biosensors being developed at Ontario’s University of Guelph are currently being licensed and they are expected to be available within a few years, said Suresh Neethirajan, director of the Bio Nano Laboratory at the university.

He said biosensors based on nanotechnology are set to revolutionize the farm and food sector.

The mandate of the Bio Nano Laboratory is to enhance animal health and food safety through nanotechnology approaches.

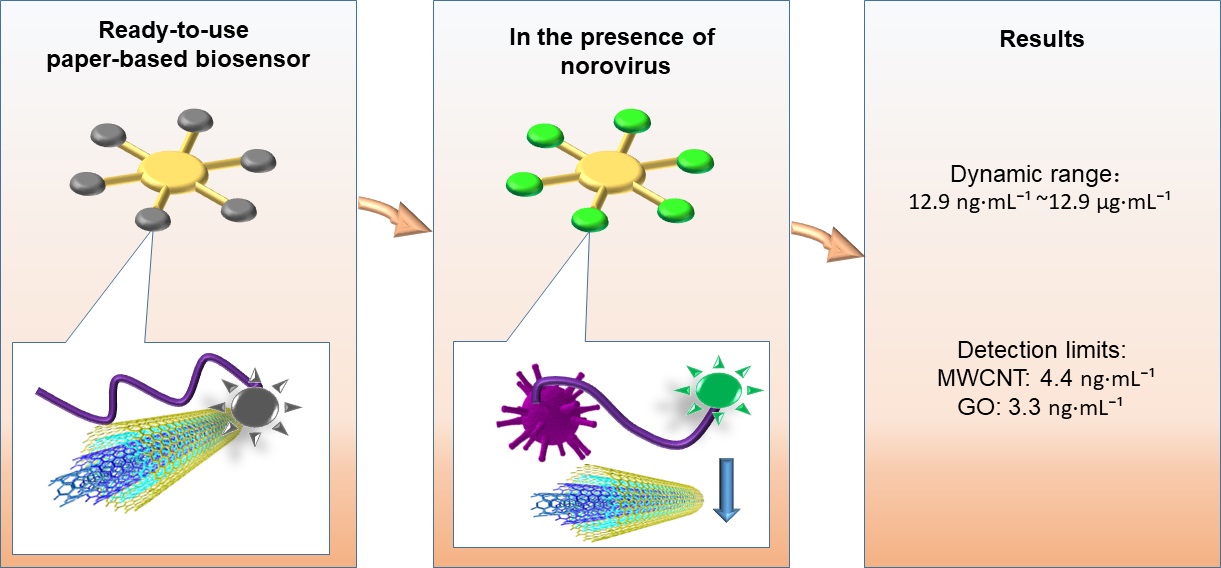

University researchers have developed a hand-held nano-biosensor that uses paper-based test strips similar to home-based glucometers. Users put a droplet of material, such as food, oral swabs from poultry, or blood solution from the dairy cow or swine, in the cartridge. Users know immediately if the specific substance or disease they are testing for is present.

Depending on which paper-based biosensor has been installed in the hand-held device, a whole hosts of pathogens and diseases can be detected — from numerous flu diseases in poultry and swine to ketosis or metabolic diseases in dairy cattle, or many kinds of food that can give allergic reactions.

Currently, when there’s an avian flu outbreak in a Canadian poultry barn it takes days to know exactly which disease is present because samples have to be shipped to a centralized animal health laboratory.

“These biosensors enable the farmers to know the results by bringing down the time for the results from several days to a few minutes, so that’s one of the key advantages,” Neethirajan said.

The biosensors offer another key advantage when it comes to infectious disease outbreaks because they can be linked in a network.

The sensors are also much easier on animals when it comes to testing because only a droplet of blood or saliva is needed.

The biosensors can also be integrated into existing monitoring systems in barns.

“That will enable the farmers to basically download an app and then periodically or in a specific frequency, it can record data in a noninvasive way.

“For example, when a bird pecks to take water, or pecks to take a grain or a seed, based on the interaction of the beak to a particular zone, we have some trace of the oral swab in fluids left over that is good enough to be able to call up in terms of screening for specific pathogenic micro-organisms,” Neethirajan said.

Biosensors are also being integrated into robot milkers in dairy barns, and can be installed on wearables such as a dairy cow’s collar.

The hand-held device developed by the Bio Nano Laboratory has biosensor cartridges that can screen for a variety of allergens such as peanut, shrimp, and gluten in food, which is particularly useful in areas with limited resources, such as remote communities.

The Bio Nano Laboratory has also developed paper-based biosensors that children with food allergies can use.

“They can dip the paper in the food solution, based on the colour change they can decide whether to eat or not to eat,” Neethirajan said.

Food processors can integrate these nano-biosensors into production lines to look for specific materials, which could dramatically change how food manufacturers test, he said.